An Almost Forgotten Step in the Evolution of Grain and Forage Crop Harvesting

By Doug Hoelscher

In the early days of farming, after clearing the land of trees and other overgrowth, perhaps the most labor intensive operation was the harvesting of grain and forage crops. There were no machines such as combines, field choppers or balers to move through the field and separate the grain from the chaff or to chop or bale hay and straw. When machines first became available to perform these tasks, they were stationary, such as corn shredders, balers, threshing machines, etc. Hay needed to be cut by hand or by horse drawn equipment, dried in the field, loaded by hand and moved to the barn for storage. Barns were equipped with hay forks or slings on ropes that could be raised by horses to dump the loads in the haymow. Wheat and oats had to be tied into shocks (bundles), loaded by hand and hauled to the barn for threshing. Loading by hand was very labor intensive, and pulling wagons with horses was extremely slow.

Then came the invention of the buckrake, which was made of long wooden teeth spaced about ten to twelve inches apart. The rake was anywhere from eight to twelve feet wide and could be loaded by pushing it into the material to be loaded such as hay, corn shocks or wheat shocks until the rake was full. It was then raised by mechanical means or dragged to the barn. The very early buckrakes were pulled between two horses. This eliminated the hand loading, but the trip to the barn was still very slow, and the loads were generally smaller than those which were loaded on wagons. Some of the farm machinery manufacturers made buckrakes to mount on the front or on the rear of tractors, which was somewhat faster than horses. John Deere called these tractor mounted devices sweep rakes.

Sometime around the late 30’s or early 40’s farmers got the idea of mounting a rake on the rear of an old car. In our area this complete machine was called a buckrake. These buckrakes were very common, and many old cars and trucks that had been traded in, wrecked or discarded were recycled into these time saving machines for farm use. Probably the most commonly used car for this purpose was the Model A Ford, which was manufactured from 1928 through 1931. These Fords were cheap and plentiful, and I have been told that many of them were scrapped for 5 dollars each. Clarence “Snuffy” Makley, an owner of a former welding shop in St. Marys, told me that he had personally converted more than 300 Model A Fords to buckrakes, and some of them were very nice cars when he started. One disadvantage of the Fords was that they were lightweight cars with only a four cylinder engine, so if the rake was loaded too heavily the front end wouldn’t stay down, and they couldn’t be steered. My dad and our neighbor Raymond “Jackrabbit” or “Jackie” Hoelscher had Buicks, which were much heavier cars with six or eight cylinder engines, and they could handle much heavier loads.

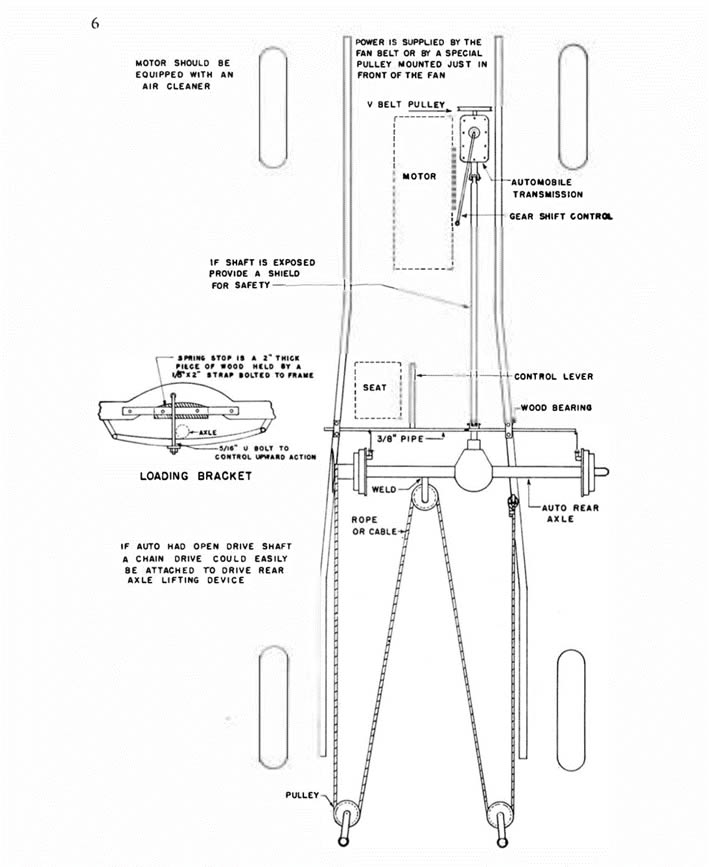

The most common method of lifting the rake used a differential and rear axle from another automobile. The differential was mounted above the frame behind the driver’s seat, and it was powered by a V-belt driven shaft from the front of the engine or by a belt or chain drive from the driveshaft of the buckrake vehicle. Sometimes the shaft passed through a car transmission to reduce the speed. A winch drum was mounted on one end of the axle to wrap a cable which passed through a series of three pulleys, and the other end of the cable was anchored to the frame. A single lever controlled the brakes on the lift axle, applying the brake on one side or the other. When the brake on the opposite end from the winch drum was applied the rake was raised. When the desired height was reached, the winch side brake was applied to hold the position of the load, and the opposite side turned freely.

The following diagram from a 1944 South Dakota State University agricultural bulletin demonstrates the principle much better than I can explain it in words.

Buckrake diagram from a 1944 South Dakota State University Agricultural Bulletin

The design and use of these machines was limited only by the imagination of the farmers building and using them. My dad built a large wagon box with only a rear axle, and he could remove the rake from the Buick and pull the wagon box on a fifth wheel hitch like a semi trailer. Later he mounted the box on a wagon running gear, and we used it for hauling grain and as a chopper wagon for hay, straw, and corn silage. These converted autos proved to be a great time saving method of moving material until field machines were introduced. By the mid-fifties very few buckrakes were still in use in our area.

Regrettably, I was born too late to experience the buckrake era and all the fun my dad and the neighbors had hot-rodding and racing them. Below is the extent of my buckrake experience. That’s me at the age of 3 behind the wheel of Dad’s 1931 Buick, and it’s the only picture I have of it.

Doug Hoelscher, age 3, behind the wheel of Dad’s 1931 Buick

Noah Settlage had a 1929 Buick. Below are three good views of it.

Loading in the field. The cable and pulleys for lifting the rake are clearly visible.

Full load ready to go to the barn.

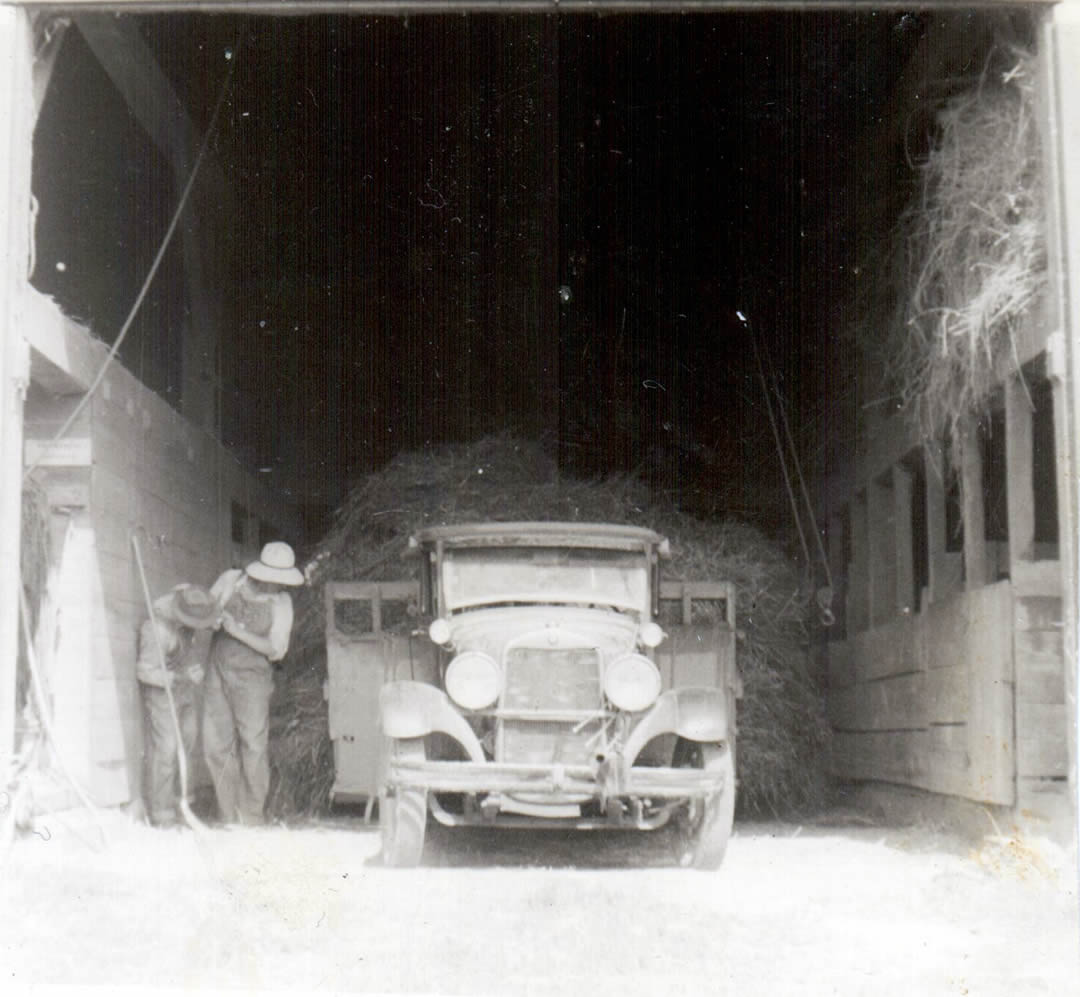

Backing into the barn.

Some of these cars had an overheating problem, so farmers would add a large tank to increase coolant capacity. I believe this to be the reason for the tank on the driver’s side running board.

Below is a photo of Gustave Schroer’s buckrake with his daughter Lois Schroer Paulat loading hay in 1952. The Schroer buildings, which are located just southwest of the intersection of Botkins and Kettlersville roads, are visible in the background.

Gustave Schroer's buckrake.

Reuben and Larry Henschen and their buckrake.

Art Fledderjohann driving his buckrake.

Reuben Bierbaum on his buckrake. The car axle and the cable for lifting the rake are clearly visible.

Another Bierbaum buckrake, obviously built from a pickup truck. The rake is removed, and a trailer is connected to a fifth wheel hitch. Reuben’s niece Gretchen Bierbaum is in the foreground.

Walter Henkener's buckrake vehicle with daughters Marilyn, Jean and Sharon.

Front view of Harry Schrolucke’s loaded buckrake

Rear view of Harry Schrolucke’s buckrake